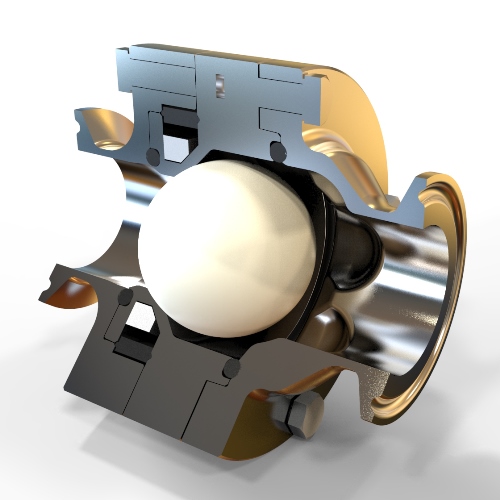

PHARMABALL VALVE

PHARMABALL CHECK VALVE

Ygros PHARMABALL: The high purity evolution of Ygros

The innovative springless non-return valve for sterile applications.

Unbeatable hygiene in design, finishes and materials used. This check valve is suitable for all mounting positions (even vertically with downward flow). For fluids and gases. Finally a truly hygienic solution, suitable for the most critical pharmaceutical applications.

The technology patented by YGROS sets new standards in the world of plant engineering, thanks to a magnetic principle that replaces the function of the spring.

- No more springs that can break or jam.

- No intermediate components to prevent flow

- No stagnation points.

- No maintenance required.

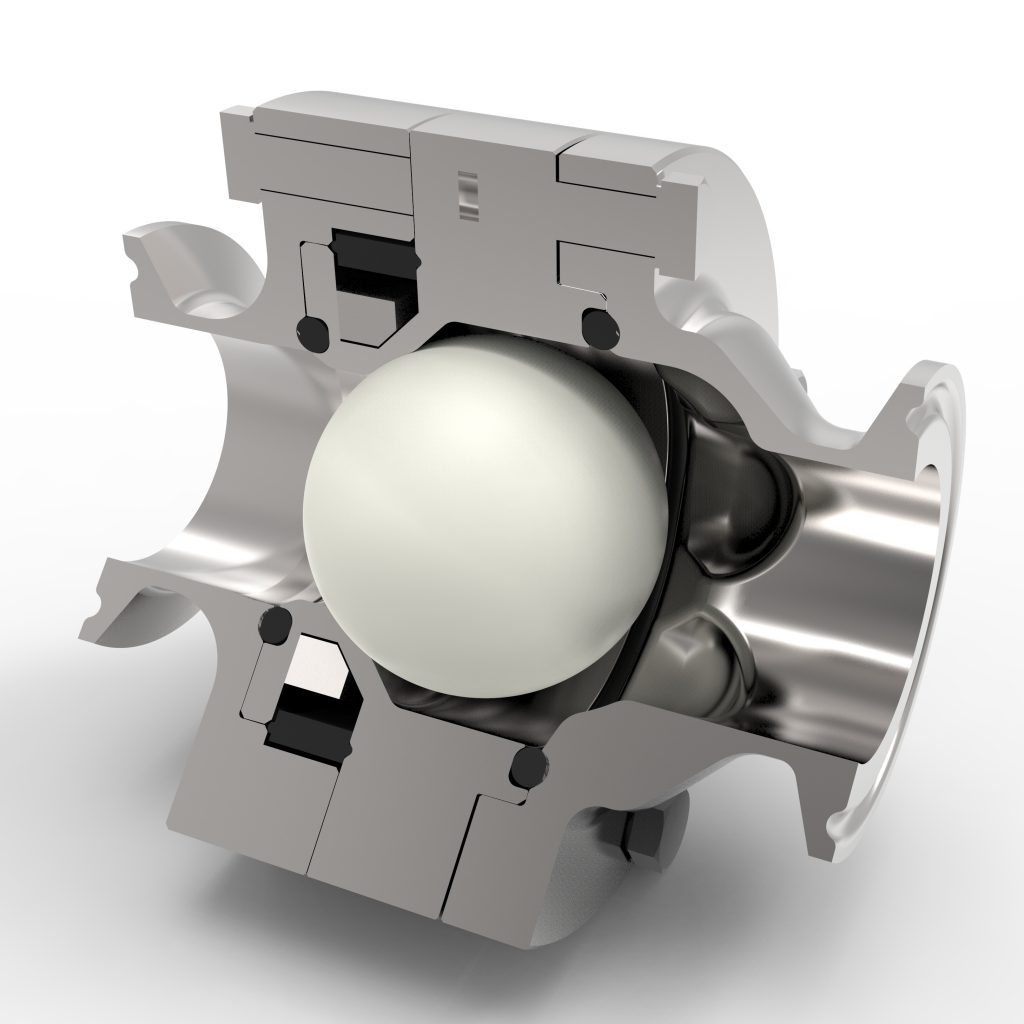

BENEFITS

- Maximum sterility: Only the shutter comes into contact with the product. No stagnation points, no springs or other intermediate components that could contaminate it. Our pharmaceutical valve also convinces with high-level surface finishes and the use of particularly hygienic materials such as 1.4435 (AISI 316 LM with ferrite content (1%)

- Closing guarantee: Secured by the patented magnetic principle

- Free Positioning: Unlike other types of springless valves (such as ball valves), Ygros Pharmaball retains its functionality on both horizontal and vertical installations.

- Energy saving: Operating principle and innovative design allow a fluid and free passage, thus minimizing turbulence and pressure drops

- Laminar flow: Minimizes turbulence

- It does not require maintenance

- Very high chemical resistance and long life of the valve: derived from the use of particularly tough materials such as 1.4435 (body and flange) and PVDF (shutter)

TECHNICAL DATA

|

Materials in contact with the product |

Body and flange: Stainless steel

1.4435 (AISI 316LM), max <1% ferrite

|

|

Materials not in contact with the product |

Magnet: Neodymium |

|

Gaskets |

EPDM, NBR, HNBR, VMQ (Silicone), FKM (Viton), FEP, PTFE |

|

Surface finishes |

Internal: Ra µm ≤ 0.4

(passivation on request)

|

|

Flanges available |

TO WELD DIN 11850 (DIN 11866

Reihe A)

|

|

Temperature Range |

-40 ° C / + 150 ° C |

|

Operating pressure |

PN16 (standard). Other pressures on request |

|

Treated products |

Liquids |

|

Certificates (on request) |

MATERIALS: (EN10204-3.1) / PVDF

ball O-Ring (FDA – USP VI)

|

Full traceability for all metal components and gaskets

| YGROS PHARMABALL: STANDARD OPENING PRESSURES Test with water at 20 ° C (68 ° F) | ||

| Installation | Direction of flow | Opening pressure |

| HORIZONTAL | 30/50 mbar | |

| VERTICAL | Descending Flow | 27/45 mbar |

| VERTICAL | Ascending Flow | 33/55 mbar |

| Once the valve is open, a pressure of about 10 mbar will be enough to keep it running. | ||

Full traceability for all metal components and gaskets

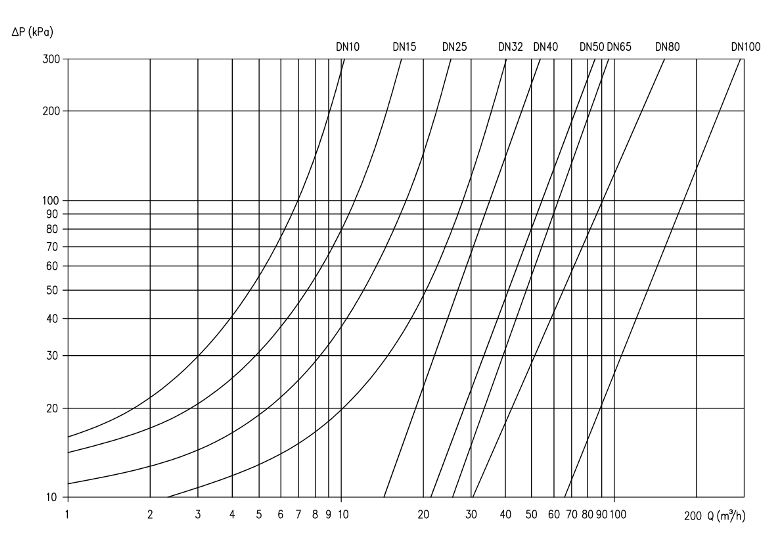

PRESSURE LOSS GRAPH

Test with water at 20 ° C (68 ° F) on horizontal pipes

CONTACT US

Contact

For any kind of query, contact us with the details below.

- 9740066460

- shivakumar.pk@sangamainc.com

- #77, 4th cross Shriniketh Layout Singapura - 97

Request a quote